The TYC no - leakage double - shell magnetic submerged pump. It features a double - shell design for enhanced safety. Magnetic drive ensures no leakage. High - quality materials guarantee durability. Efficient operation meets various fluid transfer needs.

MOQ:

1Emballer:

CustomziedCouleur:

CustomziedMatériel:

SteelTempérature de travail:

-20 to 350 ℃Pression de travail:

1.6 to 5 MPa

Product overview

The TYC no-leakage magnetic drive submerged pump is a type of submerged-structure pump, specifically designed for applications where the medium needs to be completely sealed to prevent any leakage during transportation. The submerged portion that comes into contact with the liquid is entirely made of stainless steel, and the submerged depth can vary from 1 to 6 meters. The main components of the pump are all situated within the liquid, featuring a static seal design. Without a traditional mechanical seal, the medium is completely isolated from the external air, thereby achieving true leak-proof operation.

Product advantages

1. The TYC no-leakage magnetic drive submerged pump is a novel, highly efficient, energy-saving, and leak-free submerged centrifugal pump, meticulously designed in accordance with national standards.

2. The flow passage components, including the pump body, inner rotor, pump cover, impeller, isolation sleeve, and pump shaft, can be fabricated from a variety of materials such as 304, 316, 316L, 904, TA2, HC276, and others.

3. The pump body and pump cover are designed using CFD computer fluid mechanics for hydraulic components, employing modular design and precision casting techniques. This approach ensures high cavitation resistance, a smooth flow channel, and enhances the pump's corrosion and pressure resistance capabilities.

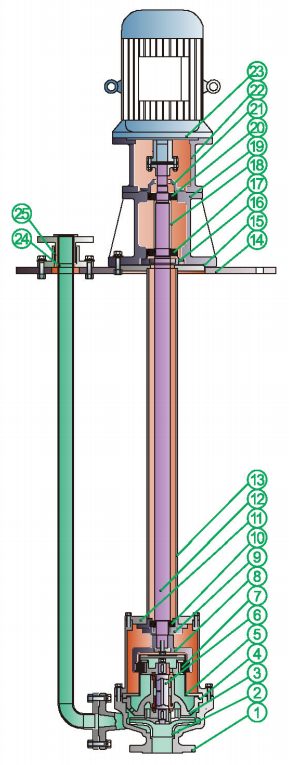

Material List

| Part | Material | Part | Material |

| ① Pump body | 304/316/316L | ⑭ Square plate | A3 |

| ② Impeller | 304/316/316L | ⑮ Sseal ring | Tetrafluoro |

| ③ Pump cover | 304/316/316L | ⑯ Bearing cover | HT200 |

| ④ Seal ring | Tetrafluoro | ⑰ Bearing | Rolling bearing |

| ⑤ Spacer sleeve | 304/316/316L | ⑱ Bearing retainer | 45# |

| ⑥ Minor axis | 304/316/316L | ⑲ Bearing housing | HT200 |

| ⑦ Inner rotor assembly | 304/316/316L/Permanent magnet | ⑳ Bearing | Rolling bearing |

| ⑧ Outer rotor assembly | 304/316/316L/Permanent magnet | ㉑ Bearing cover | HT200 |

| ⑨ Bearing cover | HT200 | ㉒ Bracket | HT200 |

| ⑩ Bearing | Rolling bearing | ㉓ Electric machinery | Per clients requested |

| ⑪ Bracket assembly | HT200/45# | ㉔ Outlet pipe | 304/316/316L/Pemanent magnet |

| ⑫ Principal axis | 2Cr13 | ㉕ Outlet flange | HT200 |

| ⑬ Executive director | 304/316/316L |

Structural diagram

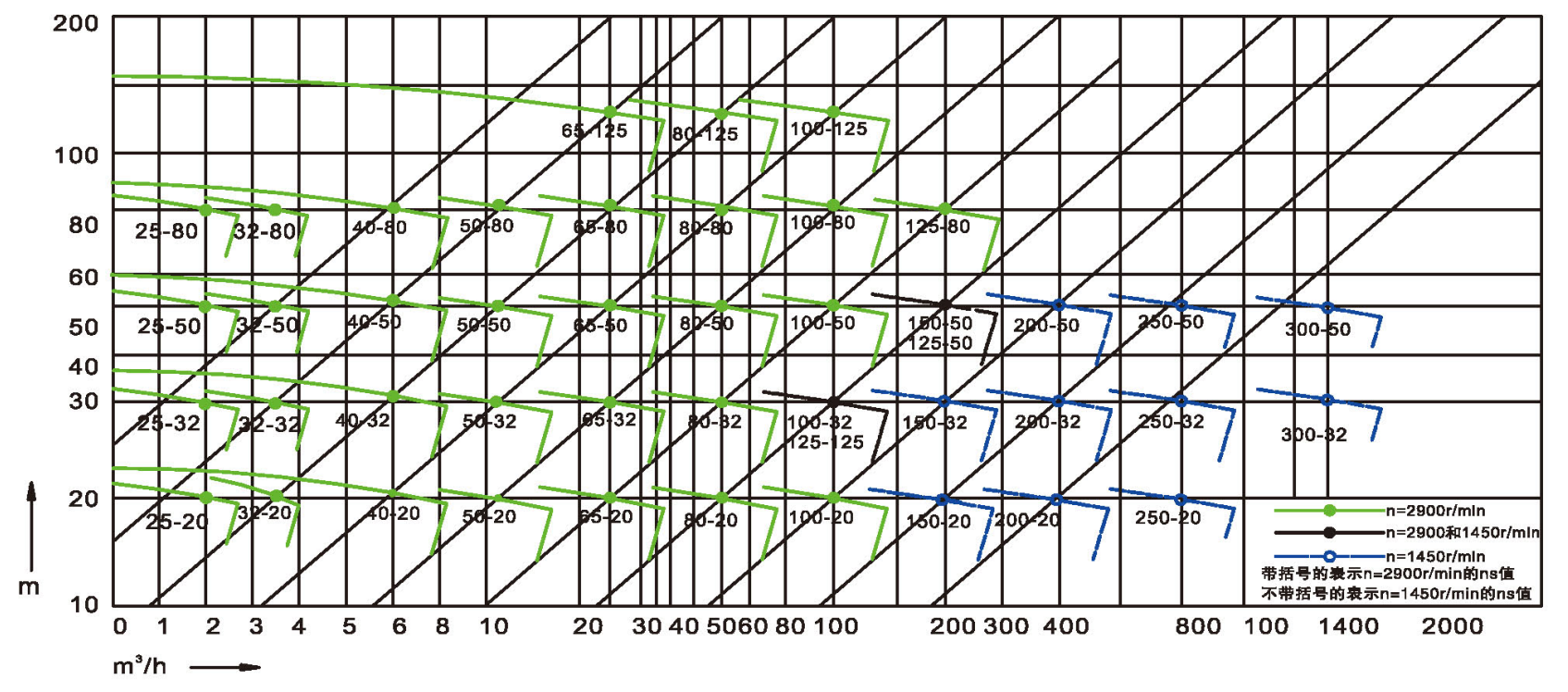

Performance range

Design pressure :1.6~5.0Mpa; Flow :1.8~400m2/h; Lift :15~125m; Power :1.5~280kw;

Applicable temperature :-20~350℃.

Product application

It is widely used in the transportation of volatile , flammable , explosive , toxic , harmful and other high - risk media in the production processes of petroleum , chemical industry , coalification , alkali making , smelting , rare earth , pesticides , dyes , medicine , scientific research institutions , national defense industry , etc.

Others