Chemical process centrifugal pump is a type of pump used in the chemical industry for transferring, discharging, feeding, and lubricating various chemicals. It operates on the principle of centrifugal force, where the rotation of the impeller throws the liquid outward, creating a pressure difference that allows the liquid to flow from the inlet to the outlet.

Paiement:

TT L/C PayPal Westunion MoneygramOrigine du produit:

China, Anhui provinceCouleur:

customizedPort d\'expédition:

shanghaiDélai de mise en œuvre:

1 monthMOQ:

1Emballer:

CustomizedCouleur:

CustomizedMatériel:

Steel/SICTempérature de travail:

-20 to 200℃/The temperature of the transportable medium is 300 ℃Pression de travail:

1.6 MPa

Product overview

The THJ chemical process centrifugal (alkali) pump is a single-stage single-suction cantilever centrifugal pump that has been upgraded and innovated based on the TH pump. It serves as a new standard chemical process pump, replacing the IH and TI pumps. This pump features a single-stage single-suction cantilever structure. In its design, an advanced hydraulic model is adopted, endowing it with high efficiency. As an energy-saving product, its efficiency is 5% higher than that of the IH pump.

Product advantages

1. The flow passage components, including the pump body, pump cover, and impeller, are crafted from high-quality stainless steel. These parts are precision-cast using a novel process, ensuring they are free from impurities, pores, and trachoma. Additionally, high-quality alloy wear-resistant materials like 2205 duplex stainless steel can be opted for.

2. The shaft seal is a proprietary 179 series static corrosion-resistant and wear-resistant mechanical seal. It allows for the selection of single or double end-face mechanical seals, as well as container-type and packing dynamic seals. For the grinding of the sealing surface, materials such as cemented carbide and silicon carbide can be chosen.

3. This pump features a corrosion-resistant and wear-resistant design, capable of transporting liquids containing slurry, crystals, and suspended solid particles smaller than 3mm, with a solid content of less than 10%.

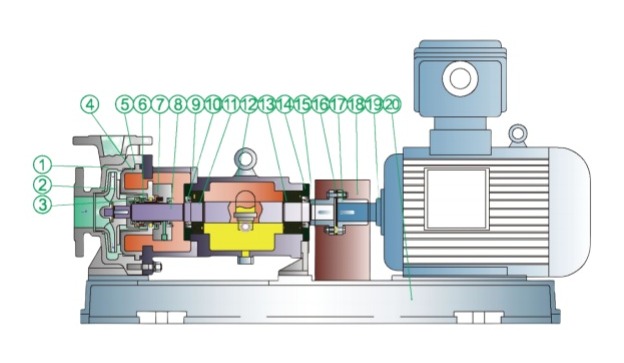

Material List

| Part | Material | Part | Material | Part | Material |

| ①Pump casing | 304/316/316L | ⑧Pump shaft | 2Cr13/3Cr13 | ⑮ Pump coupling | 45# |

| ②Impeller | 304/316/316L | ⑨Bracket | HT200 | ⑯ Diaphragm | 304 |

| ③Static ring | SIC/hard alloy | ⑩Bearing front cover | HT200 | ⑰ Elctric couping | 45# |

| ④Pump cover | 304/316/316L | ⑪ Front bearing | Gcr15 | ⑱ Shield | Hot rolled plate/Aluminum |

| ⑤Gasket | PTFE | ⑫ bearing box | HT200 | ⑲ Motor | As clients requested |

| ⑥Rotating ring | SIC/hard alloy | ⑬ Rear bearing | Gcr15 | ⑳ Plate | HT200 |

| ⑦Gland | 304/316/316L | ⑭ Rear gland of bearing | HT200 |

Structural diagram

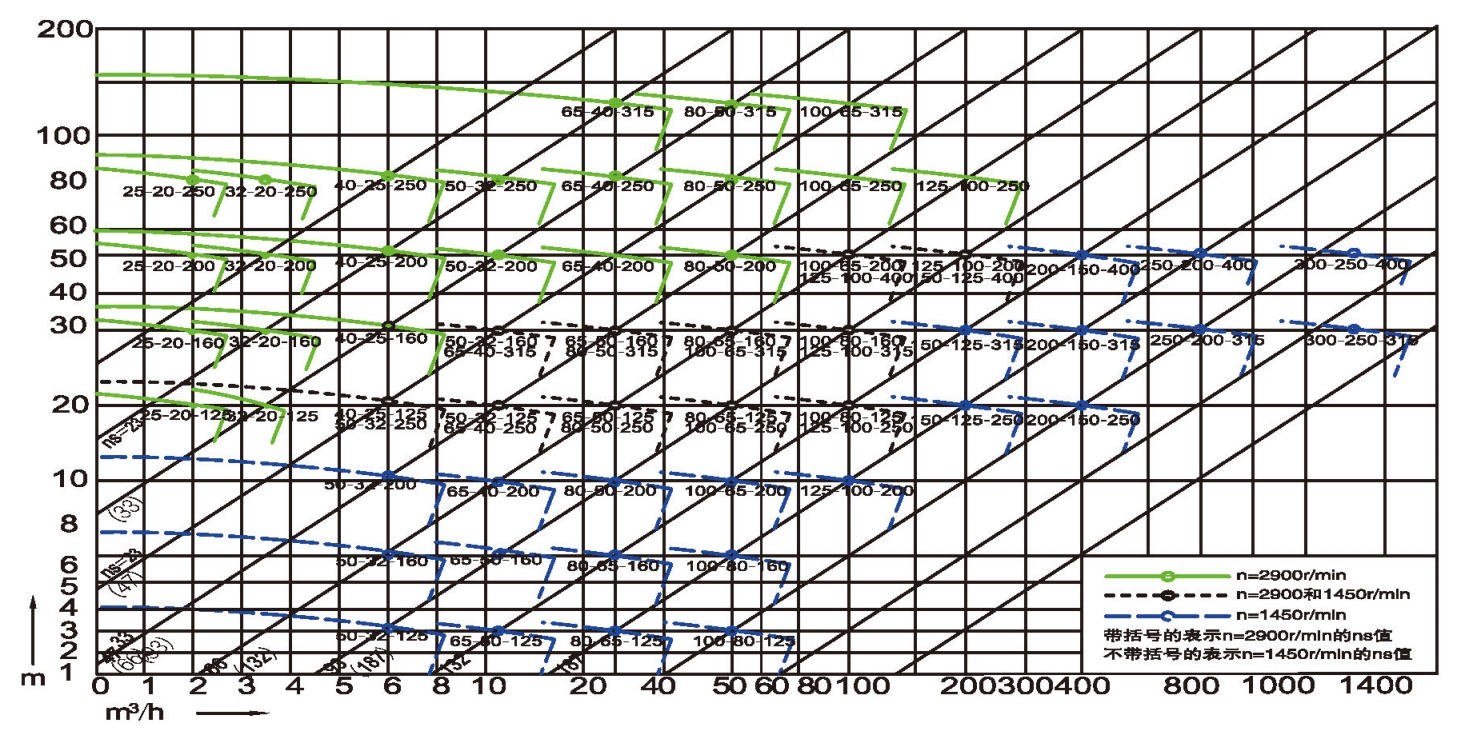

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 25-20-125 | 1.1 | 2.5 | 20 | 380V | 304/316L | 25-20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | 304/316L | 25-20 |

| 25-20-200 | 4 | 2.5 | 50 | 380V | 304/316L | 25-20 |

| 25-20-250 | 1.5 | 2.5 | 80 | 380V | 304/316L | 32-20 |

| 32-20-125 | 1.5 | 3.2 | 20 | 380V | 304/316L | 32-20 |

| 32-20-160 | 2.2 | 3.2 | 32 | 380V | 304/316L | 32-20 |

| 32-20-200 | 4 | 3.2 | 50 | 380V | 304/316L | 32-20 |

| 32-20-250 | 7.5 | 3.2 | 80 | 380V | 304/316L | 32-20 |

| 40-25-125 | 1.5 | 6.3 | 20 | 380V | 304/316L | 40-25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316L | 40-25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316L | 40-25 |

| 40-25-250 | 11 | 6.3 | 80 | 380V | 304/316L | 40-25 |

| 50-32-125 | 2.2 | 12.5 | 20 | 380V | 304/316L | 50-32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316L | 50-32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316L | 50-32 |

| 50-32-250 | 11 | 12.5 | 80 | 380V | 304/316L | 50-32 |

| 65-50-125 | 3 | 25 | 20 | 380V | 304/316L | 65-50 |

| 65-50-160 | 5.5 | 25 | 32 | 380V | 304/316L | 65-50 |

| 65-40-200 | 11 | 25 | 50 | 380V | 304/316L | 65-40 |

| 65-40-250 | 18.5 | 25 | 80 | 380V | 304/316L | 65-40 |

| 65-40-315 | 30 | 25 | 125 | 380V | 304/316L | 65-40 |

| 80-65-125 | 5.5 | 50 | 20 | 380V | 304/316L | 80-65 |

| 80-65-160 | 11 | 50 | 32 | 380V | 304/316L | 80-65 |

| 80-50-200 | 15 | 50 | 50 | 380V | 304/316L | 80-50 |

| 80-50-250 | 30 | 50 | 80 | 380V | 304/316L | 80-50 |

| 80-50-315 | 45 | 50 | 125 | 380V | 304/316L | 80-50 |

| 100-80-125 | 11 | 100 | 20 | 380V | 304/316L | 100-80 |

| 100-80-160 | 18.5 | 100 | 32 | 380V | 304/316L | 100-80 |

| 100-65-200 | 30 | 100 | 50 | 380V | 304/316L | 100-65 |

| 100-65-250 | 45 | 100 | 80 | 380V | 304/316L | 100-65 |

| 100-65-315 | 75 | 100 | 125 | 380V | 304/316L | 100-65 |

| 125-80-160 | 30 | 160 | 32 | 380V | 304/316L | 125-80 |

| 125-100-200 | 55 | 200 | 50 | 380V | 304/316L | 125-100 |

| 125-100-250 | 75 | 200 | 80 | 380V | 304/316L | 125-100 |

| 125-100-315 | 22 | 200 | 125 | 380V | 304/316L | 125-100 |

| 125-100-400 | 30 | 200 | 50 | 380V | 304/316L | 125-100 |

| 150-125-250 | 18.5 | 200 | 20 | 380V | 304/316L | 150-125 |

| 150-125-315 | 30 | 200 | 32 | 380V | 304/316L | 150-125 |

| 150-125-400 | 45 | 200 | 50 | 380V | 304/316L | 150-125 |

| 200-150-250 | 37 | 400 | 20 | 380V | 304/316L | 200-150 |

| 200-150-315 | 45 | 400 | 32 | 380V | 304/316L | 200-150 |

| 200-150-400 | 75 | 400 | 50 | 380V | 304/316L | 200-150 |

| 250-200-250 | 55 | 800 | 50 | 380V | 304/316L | 250-200 |

| 250-200-315 | 110 | 800 | 80 | 380V | 304/316L | 250-200 |

| 250-200-400 | 160 | 800 | 50 | 380V | 304/316L | 250-200 |

| 300-250-315 | 160 | 1400 | 32 | 380V | 304/316L | 300-250 |

| 300-250-400 | 200 | 1400 | 50 | 380V | 304/316L | 300-250 |